Actuator Solutions for Every Industry: Electric Linear Actuators Explained

- Home

- Linear Actuators

- Actuator as a Keystone of Motion

Contents:

- How Does a Linear Actuator Work?

- Benefits Of Electric Actuators Over Hydraulic/Pneumatic

- How to Select the Right Actuator

- Categories of Electric Linear Actuators

- How To Mount Linear Actuators Securely

- Customer Projects & Use Cases in Industry Applications

- Why Choose Progressive Automations Actuators?

- FAQ

- In Summary

Need Further Assistance?

Call Our ExpertsAn actuator is a component that helps machines to achieve physical movements by converting energy, often electrical, air, or hydraulic, into mechanical force. Simply put, it is the component in any machine that enables movement.

Sometimes, to answer the question of what an actuator does, the process is compared to the functioning of a human body. Like muscles in a body that enable energy to be converted to some form of motion, like the movement of arms or legs, actuators work in a machine to perform a mechanical action.

How Does a Linear Actuator Work?

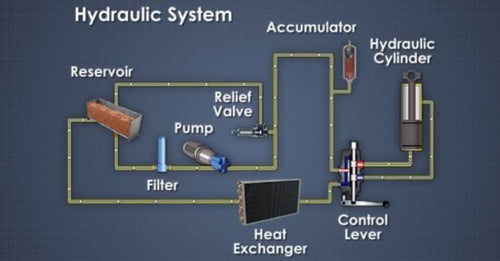

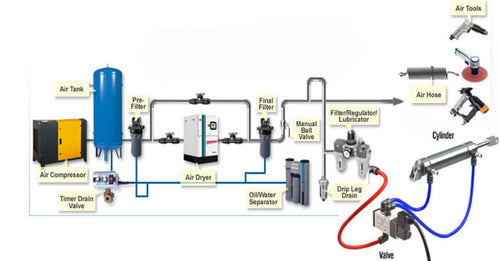

Defined simply, an actuator is a device that converts energy, which may be electrical, hydraulic, or pneumatic, to mechanical output in such a way that it can be controlled. The quantity and the nature of input depend on the kind of energy to be converted and the function of the actuator. Electric actuators work on the input of electric current or voltage; for hydraulic actuators, it's incompressible liquid, and for pneumatic actuators, the input is air.

The following are the usual components that are part of the functioning of an actuator:

- Power source: Often found in the form of hydraulic proportional valves and electrical inverters, they provide the energy that is necessary to drive the actuator. These are often electric or fluid in nature in the industrial sector and may convert their input source to an output value following the measurements set by the controller.

- Actuator: The actual device that converts the supplied energy to mechanical force.

- Mechanical load: The energy converted by the actuator is usually used to make a mechanical device function. The mechanical load refers to the mechanical system that is being driven by the actuator.

- Controller: A controller ensures that the system functions seamlessly with the appropriate input quantities and other setpoints decided by an operator.

Types of Linear Actuators

Depending on the kind of movement they make and the source of energy used to function, there are different types of actuators. Here is a list of the various types of linear actuators:

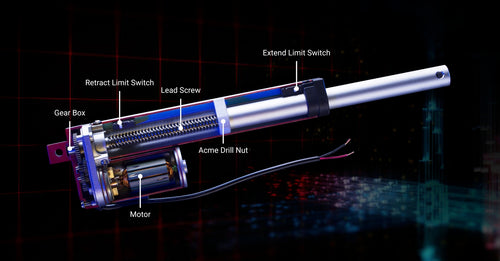

Electric Linear Actuator

As the name implies, electric linear actuators use electrical energy to enable movements in a straight line by utilizing a variety of internal components working together. They work by moving a shaft back and forth based on electrical signals. Electric linear actuators function with a motor that generates high-speed rotational motion and a gearbox that slows down its impact. This will, in turn, increase the torque that would be used to turn a lead screw, which results in linear motion of a shaft or drive nut.

Brushed and brushless DC motors are commonly used as the rotational drive of electric actuators. By using different gears, different speeds can also be achieved - higher speeds result in less force. A limit switch within the main actuator shaft at the top and lower end stops the screw as it reaches the end of its movement or stroke. As the shaft reaches its end, the switch cuts off power to the motor; however, a diode wired in parallel to the switch allows current flow in the opposite direction, so you can reverse direction when needed.

Hydraulic Linear Actuator

The purpose of a hydraulic linear actuator is the same as that of an electric linear actuator – to generate a mechanical movement in a straight line. The difference is that hydraulic linear actuators achieve this with an unbalanced pressure that is applied with hydraulic fluid on a piston in a hollow cylinder that can lead to a torque strong enough to move an external object.

The main advantage of a hydraulic linear actuator is the high amount of torque it can generate. This is because liquids are almost incompressible. Single-acting hydraulic actuators have pistons that can move in just one direction, and a spring is needed for reverse motion. A double-acting hydraulic actuator applies pressure at both ends to facilitate similar movement from both sides.

Pneumatic Linear Actuators

Pneumatic actuators are often considered to be the most cost-effective and simplest of all actuators. Pneumatic actuators use compressed air to create movement, either by extending and retracting a piston or, more rarely, using a carriage that runs on a driveway or a cylindrical tube. The retraction of the piston is either done with a spring or by supplying fluid from the other end.

Pneumatic linear actuators are best suited to achieve high speed and torque on a relatively small footprint. Quick, point-to-point motion is their strength, and they don’t easily get damaged by hard stops. This rugged nature makes them popular in devices that need to be explosion-proof or resistant to hard conditions like high temperatures.

A complete A-Z guide on how to select, test, and implement linear motion for any application. Written by engineers, for engineers.

Benefits Of Electric Actuators Over Hydraulic/Pneumatic

Ease of Use

A benefit of using electric linear actuators is the convenience they offer as a simple-to-operate alternative for producing linear motion. Standard electric actuators use a brushed DC motor and have a simple 2-wire operation to extend and retract. Wiring an actuator to a rocker switch or control box allows for a neat and tidy setup with no need for tubes, valves, or hoses found in hydraulics and pneumatics.

Although alternatives may have a lower up-front cost for producing linear motion, electric linear actuators eliminate the inconvenience of all the extra labor required for integrating them as fast drop-in solutions.

Low Maintenance

Electric linear actuators are self-lubricated internally for the life of the unit and require no maintenance when used within their ratings. This helps in saving labor time and resources over the span of the electric actuator’s service life. There are also options with waterproof Ingress Protection and salt spray ratings for more corrosion resistance in the elements. As a result, they have an improved lifespan, which reduces the need for frequent replacements.

Eco-Friendly Operation

Alternatives like hydraulics and pneumatics require more working components to operate, like heat exchangers, fluid reservoirs, regulators, and compressors. The extra materials and heat generated from more working components have a harder impact on the environment. Electric actuators ensure an environmentally friendly means of providing linear motion without any risk of polluting the ocean with oil leaks. The eco-friendly operation of electric actuators can also reduce the extra work required for certain OEMs to pass specific health and safety regulations.

How to Select the Right Actuator

When purchasing an actuator, understanding which model suits your requirements best based on the design and ratings is crucial. Here are a few key considerations on how to choose the right actuator for your needs:

- Load Requirements: Refers to how much force your application will require. This will influence your choice of the model actuator.

- Speed: Depending on the application, you might need a fast or slow linear actuator. Choose according to your application needs.

- Stroke Length: This is to indicate how far the actuator needs to move. Make sure to match the stroke length to your project’s travel distance requirements.

- Electrical Power Requirements: The voltage and current draw requirements of each model actuator can vary. Consider the voltage and power supply options available for your actuator.

- Environmental Resistance: Consider your application and the environment to determine whether your linear actuator must withstand a certain level of dust, liquid ingress, and/or corrosion.

- Positional Feedback: Determine whether your application will require a certain level of precision motion/advanced capabilities or if basic manual forward and reverse control is suitable.

- Control System Compatibility: Choose control systems that are compatible with the chosen electric actuator(s). If you have pre-existing control systems, ensure the chosen actuator(s) are compatible.

Check out our YouTube channel for overviews of our actuator lineup. We also have a downloadable guide with questions that can help guide engineers, purchasers, and operations managers in choosing from our range of linear actuators to find the most suitable model

Load Requirements

There are a couple of factors involved in finding the right force rating to handle an application’s load requirements. Variables can include the load, the angle at which the load is being applied, and the dimensional size of the load. Load requirements are measured by how much force is required to be pushed and/or pulled directly onto the shaft of an actuator (example units: lbs, kg, Newtons). Use our Actuator Calculator Tool to get initial estimations as a starting reference point for actuator models you can consider.

Speed Rating

Travel speeds usually depend on the force rating options an actuator has been configured for. Some models come with multiple force ratings options that can be selected when placing an online order. These different force rating options have their internal gear ratios adjusted to a certain torque setting that also affects the actuator's travel speed. The speed of an actuator is measured by the distance travelled over a period of time (example: inch/second, mm/second)

Stroke Length

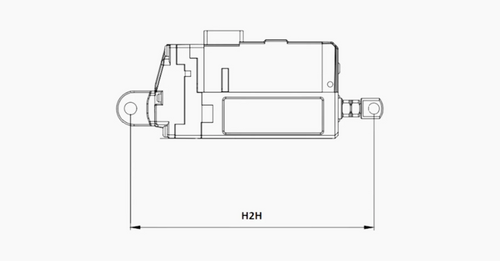

The hole-to-hole (H2H) length of an actuator measured from the center of the rear mounting hole to the center of the front mounting hole is affected by stroke length. This is because a longer stroke length requires an actuator with a longer body to house the enclosed shaft. Stroke length can be calculated by subtracting the fully closed H2H length from the fully open H2H length of the actuator (example units: inch or " for short, mm)

Electrical Power Requirements

An application may come with a pre-existing source of electrical power or will have a newly installed power supply with certain electrical power ratings and requirements. Check the voltage (VDC or VAC) and current (Ampere or A) ratings of the power source(s) and actuator(s) to verify if they are within a suitable range. The general rule of thumb is that the power supply needs to have a higher current rating than the combined maximum current requirement of all the units connected to the power supply.

12V vs 24V Actuators: Which One Should You Choose?

Environmental Resistance

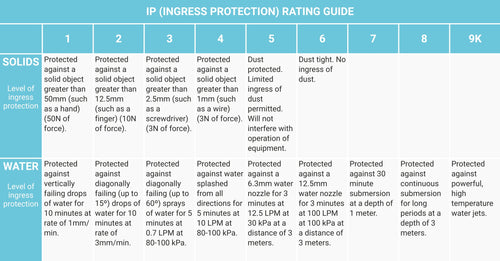

The Ingress Protection (IP) rating system uses a 2-digit system to define its protection rating for all products. The first digit represents protection against solids, and the second against liquids. The IP Code was designed to standardize protection ratings and limit misinterpretation/misrepresentation of a product's protection ability. Salt spray rating is crucial for protection against corrosion that may occur from salted roads, beaches, salt water, etc.

Positional Feedback

Built-in positional feedback devices like encoders, hall effect sensors, potentiometers, etc., are used for transmitting signals that will be read by a controller to determine the position of the actuator’s stroke. This allows for capabilities such as multiple actuators that can simultaneously travel at the same speed together in synchronous motion, memory presets, and/or positional display.

Control System Compatibility

Check if your actuator has the matching communication protocols/positional feedback to the controllers you were considering. For example, the PA-12-T (TTL/PWM) and PA-12-R (RS-485) Micro Precision Servo Actuator provide precise position control with positional accuracy up to 100 μm and require advanced communication protocols for such performance. Another thing to consider is whether the type of motor your actuator has will be compatible with a control system. Continuously operating brushless motors such as those found in our PA-14 custom linear actuators would require control boxes compatible with their operation such as the LC-241 control box.

To see which of our control boxes and actuators are compatible with each other, check out our control box comparison and compatibility charts below:

Programmable Functions

Control boxes such as our FLTCON series allow for the ability to have programmed functions, safety features, and other user settings that can be accessed through the connected remote control. When multiple Hall-effect-type actuators are connected to an FLTCON control box, the control box ensures the synchronization of the motors so they move together at the same speed.

Basic Manual Controls

Consider if there were any budget constraints for the project, and choose a control system that offers the best value for your investment while meeting your performance requirements. For example, simple indoor projects that do not require high precision would work without any issues by wiring a basic rocker switch without high ingress protection to control a 2-wire micro or mini linear actuator at an affordable price.

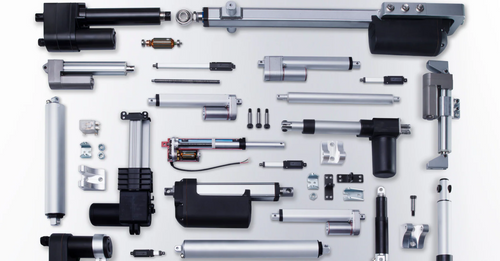

Categories of Electric Linear Actuators

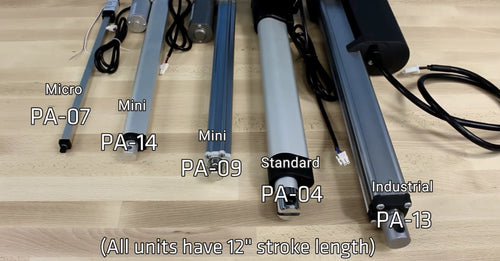

Electric linear actuators come in a wide variety of designs, each engineered to meet specific performance requirements, environmental conditions, and space constraints. From compact micro units that fit into the tightest spaces to heavy-duty industrial models capable of moving thousands of pounds, each category offers unique strengths and applications.

Factors such as form factor, force capacity, stroke length, and operating environment all play a role in determining the right actuator for the job. Understanding the characteristics and specialties of different actuator types—such as tubular, micro, industrial, mini, standard, track, and telescopic—can help you choose the best solution for your project, whether it’s for precision robotics, large-scale machinery, or custom automation systems.

To compare our different models of linear actuators, we have our compare actuators tool and compiled a reference actuator comparison chart.

Micro Actuators

Micro actuators are designed for applications where space is extremely limited. Their small form factor allows for integration into compact systems, though this comes at the expense of force output, which is generally in the low to medium range. Variants of micro actuators can excel at high precision positioning rather than heavy lifting and are often chosen for their lightweight construction and adaptability.

Mini Actuators

Mini actuators bridge the gap between micro and standard actuators, offering a balance of compact size and moderate force capabilities. Their design allows them to fit in applications with limited installation space while still delivering performance suitable for a variety of automation needs. Mini actuators offer flexibility without sacrificing too much on force or stroke length, making them a versatile option for medium-duty, space-conscious designs. We also have an online quiz with questions that can help guide you in choosing from our range of micro and mini actuators to find the most suitable model for your needs.

Standard Actuators

Standard actuators are the most common and versatile category, designed for general-purpose use across a wide range of industries. They come in numerous stroke lengths and force ratings, with broad compatibility for control systems and easy integration into both simple and complex setups with feedback functions. Their balanced combination of performance, availability, and affordability makes them the go-to choice for projects that require reliability without specialized constraints.

Industrial Actuators

Industrial actuators are built for heavy-duty applications that demand maximum force and high weather resistance. They are engineered with robust materials, high-capacity motors, and strong gear systems capable of producing forces that may exceed 3000 lbs. Many are designed with customizable mounting options and compliance with industrial standards. In environments where uptime and load capacity are critical, industrial actuators offer the durability and reliable performance necessary for demanding conditions in harsh environments.

Tubular Actuators

Tubular actuators feature a cylindrical housing that gives them a sleek, low-profile appearance, making them both functional and aesthetically pleasing. Their enclosed design often comes with higher ingress protection ratings, such as IP65 or greater, offering reliable resistance against dust and water. A tubular design allows for a more compact width and height in exchange for a longer overall retracted length. This makes them well-suited for outdoor environments or applications where the actuator will be exposed to the elements and installations with limited width and height space.

Track Actuators

Track actuators operate differently from traditional rod-style designs, using an internal sliding carriage to create movement within a fixed-length body. Because their body length does not change with the stroke, they are ideal for situations where extension space is limited. This design enhanced stability as the moving carriage has multiple points of contact with a pre-defined path rather than being suspended in the air. Since the open architecture of track actuators is more sensitive to dust and water compared to sealed conventional designs, track actuators are better suited for indoor applications.

Telescopic Actuators

Telescopic actuators employ multiple nested stages of shafts that extend from within one another, much like the sections of a telescope. This enables them to achieve long stroke lengths without requiring a long-retracted length, making them ideal for applications with severe space constraints when stored. Similar to lifting columns, they are often more mechanically complex but offer unique capabilities that standard actuators cannot match. By combining compact storage with large extension capabilities, telescopic actuators provide an effective solution for reaching farther in tight applications.

How To Mount Linear Actuators Securely

The simplest way to ensure you have the correct mounting brackets for your linear actuator will be to source your mounting brackets from the original manufacturer of the actuator and verify they are compatible. For more information, we offer our mounting brackets compatibility chart and product descriptions under each of our actuators. Other manufacturers may also have similar sources; however, you can also reach out for customer support as needed. For certain cases, users with unique requirements or specialized applications may have to consider custom-making their own brackets according to the measurements, design, and shape they need. Check out our actuator 3D drawings as a source for additional reference.

Equally important to sourcing compatible mounting brackets for your linear actuators is selecting the mounting process with a method that is right for your application. Below are two common methods that are used to mount an electric linear actuator.

- Dual pivot mounting

- Stationary mounting

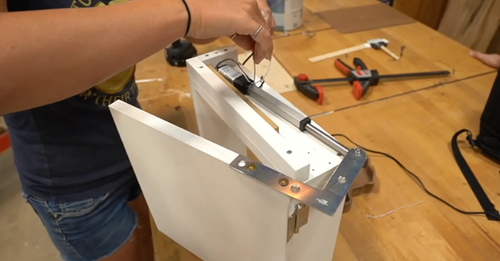

Dual Pivot Mounting

Dual pivot mounting is a method that involves fixing an actuator on both sides with a mounting point that is free to pivot, which usually consists of a mounting pin or a clevis. Dual pivot mounting allows the actuator to pivot on either side as it extends and retracts, allowing the application to achieve a fixed path motion with two free pivot points.

One example application of this method is to automatically open and close chicken coop doors. When the actuator extends, the dual fixed points enable the door to swing open. The action of the door closing and opening causes changes in angle, but the pivot provides ample space for the two mounting points to rotate. While using this method, make sure that there is enough room for the actuator to extend, without any obstacles on its way.

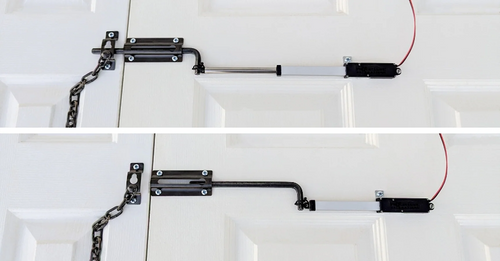

Stationary Mounting

For the stationary mounting method, the shaft can extend and retract from the housing in a straight line path while the rest of the actuator is mounted in a fixed stationary position. A mounting bracket for the shaft housing may be used to help maintain the ideal alignment of the actuator in place on a mounted surface. This kind of mounting is commonly used to achieve actions like pushing and pulling an attachment head-on. For instance, this form of mounting is ideal for pushing and pulling a sliding door latch to lock and unlock a door. When deciding on this method, ensure that the mounting apparatus can handle the load being applied by the actuator.

Customer Projects & Use Cases in Industry Applications

The versatility of electric linear actuators with efficient operations, durable construction, customization options, and high performance specifications opens a world of endless possibilities. Here are a few example applications and industries where they are used:

- Home Automation: The added convenience and safety of having security door locks, motorized louvered roof pergolas, automatic doors, and window shades make actuators popular solutions for smart homes. Home appliances like TVs can be placed at optimum height without hassle using TV lifts that make use of linear electric actuators. There are also table lifts that use actuators to adjust the height to the needs of users.

Applications of Electric Actuators in Home Automation:

- Custom/DIY Projects: In many cases, prototyping a new product or creating small-scale versions is a critical step in the process of helping determine potential challenges that may need to be addressed before proceeding with a finalized project. Custom amusement parks and Halloween costumes utilize animatronics, movie robots, and special effects props that captivate an audience through life-like motion.

- Medical industries: In the medical field, precision control of micro actuators is critical for equipment designed for handling fluid flow, driving surgical robots, or positioning medical equipment. Adjustable beds, chairs, rehabilitation equipment, and imaging equipment may incorporate mini actuators for driving quiet and smooth motion in hospital settings.

- Automotive Industries: Automotive applications come in a variety of different use cases and require innovative solutions with custom linear actuators tailored to keep up with their growing demand. Use cases can include opening storage compartments, raising campers, mirror tilting, window adjustments, seat adjustments, and automating roof conversions.

- Marine Applications: The waterproof and water-resistant design options combined with versatile performance capabilities also make electric linear actuators popular in marine applications and OEM use cases. F wakeboard towers, interior compartments, and reverse controls, actuators offer flexibility and clean operations that comply with marine and environmental regulations.

- Manufacturing Industry: Manufacturing plants use them in material handling, such as cutting equipment that moves up and down, and valves that control the flow of raw materials. Robots and robotic arms, both within and outside the manufacturing industry, also make use of linear actuator systems to achieve movement in a straight line.

- Renewable Energy: Solar tracking systems are essential in modern solar energy installations, designed to optimize the alignment of solar panels with the sun to maximize energy capture. Electric linear actuators significantly enhance the functionality of these systems by providing precise control, advanced automation, and robust safety features.

Why Choose Progressive Automations Actuators?

At Progressive Automations, quality is at the core of everything we do. From day one, we’ve built a quality-obsessed organization with a strict set of standards, aiming for nothing but the best for our customers and striving toward continual improvements. Because of this, we are excited to announce that Progressive Automations is now ISO 9001:2015 certified! Meeting and exceeding this set of standards is what enables us to consistently outperform customer expectations.

As a global brand with a dedicated presence in the USA, Canada, and Australia, Progressive Automations stands out for a wide selection of electric linear actuators, including heavy-duty, micro, and tubular models. With fast shipping, expert support, and tailored OEM actuator solutions, we are a go-to electric actuators supplier for industries ranging from home automation to industrial manufacturing. Our commitment to quality and customer experience makes us a top choice among actuator systems providers.

FAQ

A linear actuator is a mechanical component that converts energy into straight-line movement, allowing you to push, pull, lift, or position loads.

Controls for an actuator will vary depending on what type of actuator is being used; however, our control systems guide will help give directions for selecting the suitable controls for your needs.

The three main styles of actuators popular in the industry include hydraulic, pneumatic, and electric actuators.

Consider a checklist to record your application requirements and then find the most suitable type of actuators based on whether their rated specifications match your listed requirements.

If stock actuators do not meet your needs, we also offer custom linear actuators!

In Summary

Actuators are critical components in our day-to-day life for driving the motion and mechanical operations of everyday technology. By understanding the different types of actuators, their specifications, and the process of selecting suitable models, users can ensure optimal operation and achieve the results that meet the needs of their application.

We hope you found this as informative and interesting as we did, especially if you were looking for guidance in choosing suitable actuators for your application. If you have any queries about our products or have trouble picking out the right electric linear actuators to suit your needs, feel free to reach out to us! We are experts in what we do and will be happy to help with any questions you may have!

sales@progressiveautomations.com | 1-800-676-6123