FLTCON-2-24VDC Specifications

The FLTCON-2-24VDC is a 2-channel Hall effect control box that synchronizes travel between two identical linear actuators, lifting columns or table lifts. We’ve specifically designed this unit to overcome common challenges found in many actuator control box solutions with hall effect feedback, such as:

-

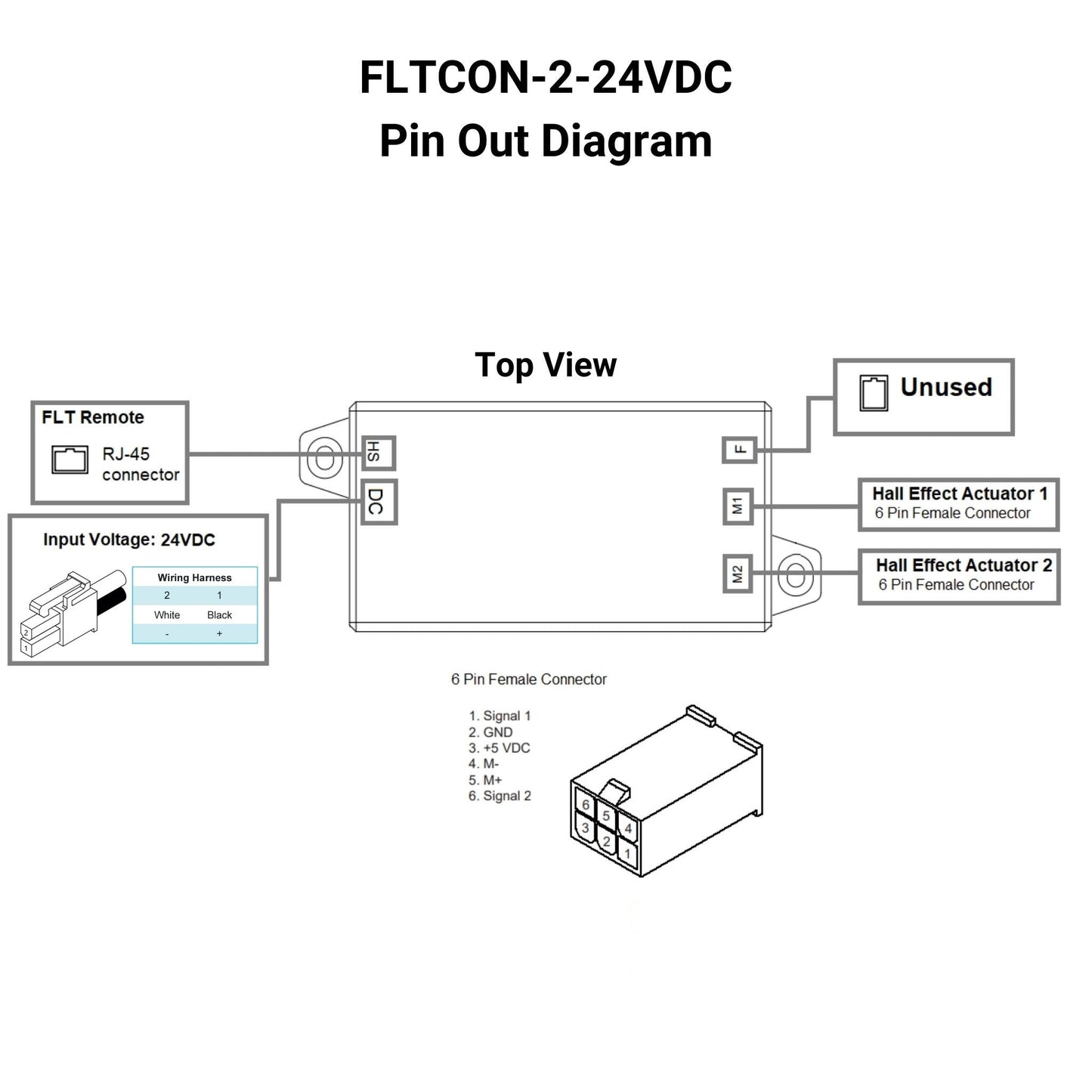

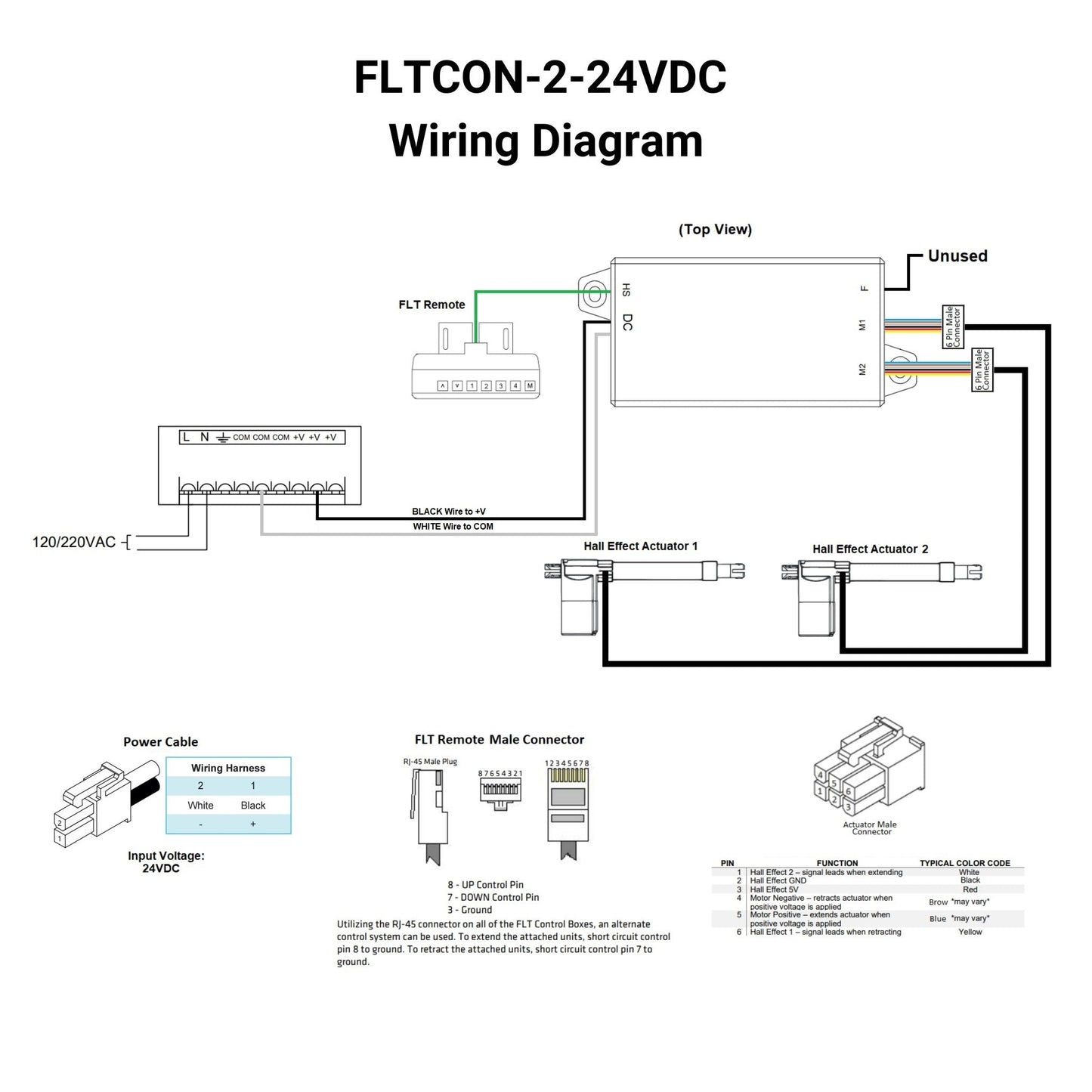

Easy Setup: Plug-n-play connectors of our hall effect type actuators and FLTCON control boxes allow for fast and simple wiring to your system.

-

Control Type: The FLTCON control boxes come with an RT-11 remote that offers stylish designs, an LED display, and programmable features.

-

Smart Safety Features: The FLTCON series of control boxes are designed with smart safety features such as overcurrent and overheat/duty cycle protection.

Key Benefits and Features of the FLTCON-2-24VDC

- Actuator Compatibility: The 24VDC output allows compatibility with a wide range of 24 VDC type hall effect actuators and columns.

- Input Voltage: Accepting 24VDC input voltage ensures the FLTCON-2-24VDC can be paired with 24VDC supplies for mobility.

- Dual Hall Effect Control: 2 matching hall effect actuators can be simultaneously controlled to travel together synchronously.

- Current Draw: The FLTCON-2-24VDC control box output channels have a current draw rating of 10A each while the control box can handle 15A total.

-

Programmable Settings: Our FLTCON control boxes allow for programmable features such as memory presets when paired with the included RT-11 programmable wired remote.

Please contact sales@progressiveautomations.com.au for programming requirements for this product.

FLTCON-2-24VDC Specifications

The FLTCON-2-24VDC is a 2-channel Hall effect control box that synchronizes travel between two identical linear actuators, lifting columns or table lifts. We’ve specifically designed this unit to overcome common challenges found in many actuator control box solutions with hall effect feedback, such as:

-

Easy Setup: Plug-n-play connectors of our hall effect type actuators and FLTCON control boxes allow for fast and simple wiring to your system.

-

Control Type: The FLTCON control boxes come with an RT-11 remote that offers stylish designs, an LED display, and programmable features.

-

Smart Safety Features: The FLTCON series of control boxes are designed with smart safety features such as overcurrent and overheat/duty cycle protection.

Key Benefits and Features of the FLTCON-2-24VDC

- Actuator Compatibility: The 24VDC output allows compatibility with a wide range of 24 VDC type hall effect actuators and columns.

- Input Voltage: Accepting 24VDC input voltage ensures the FLTCON-2-24VDC can be paired with 24VDC supplies for mobility.

- Dual Hall Effect Control: 2 matching hall effect actuators can be simultaneously controlled to travel together synchronously.

- Current Draw: The FLTCON-2-24VDC control box output channels have a current draw rating of 10A each while the control box can handle 15A total.

-

Programmable Settings: Our FLTCON control boxes allow for programmable features such as memory presets when paired with the included RT-11 programmable wired remote.

Please contact sales@progressiveautomations.com.au for programming requirements for this product.

Following a set of standards is crucial for businesses to ensure their products and services can meet a level of quality that promotes customer satisfaction. At Progressive Automations, we aim for nothing but the best for our customers and strive toward continual improvements. Because of this, we are excited to announce that Progressive Automations is now ISO 9001:2015 certified!

Quality You Can Trust – Learn MoreVideos

Related blog articles: