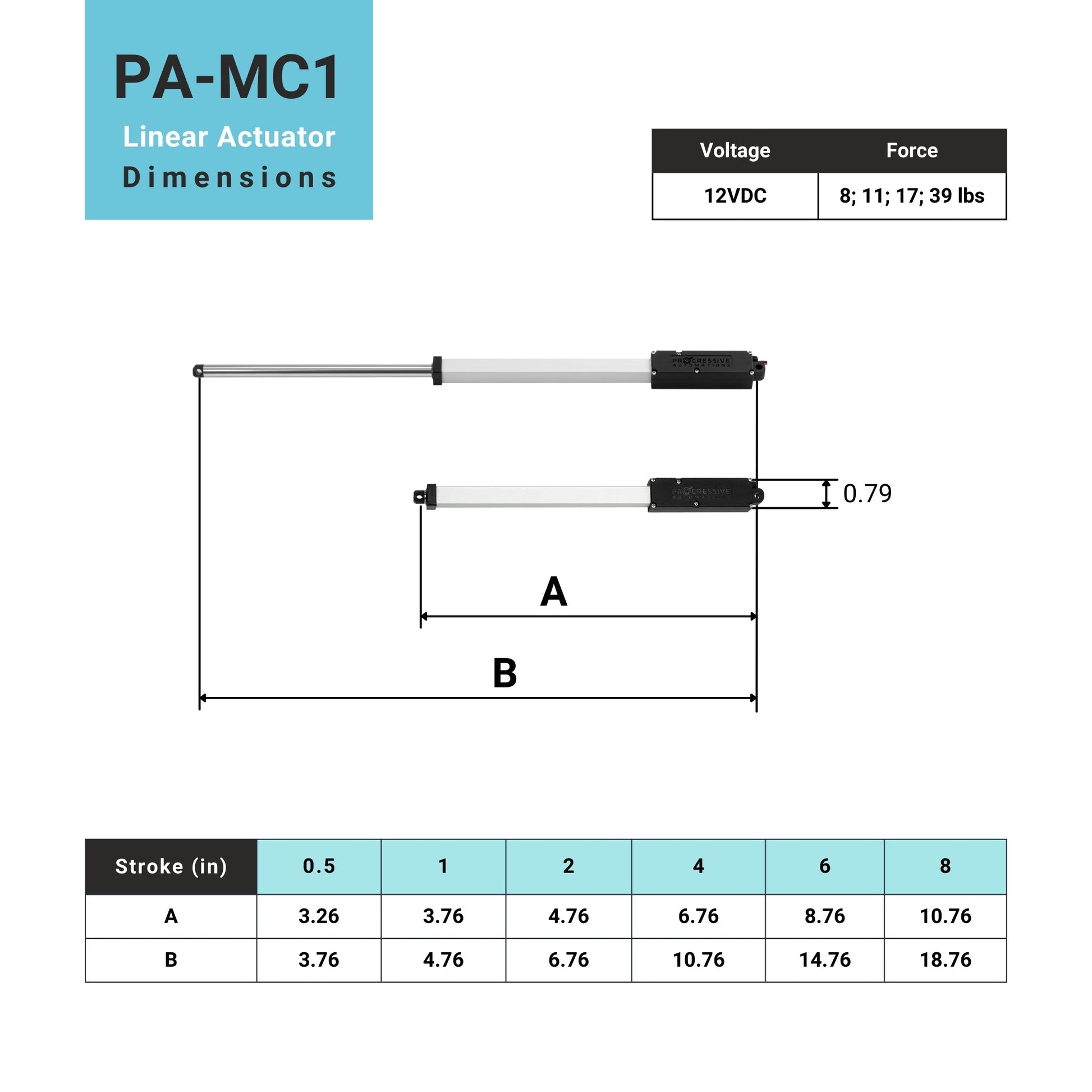

PA-MC1 Specifications

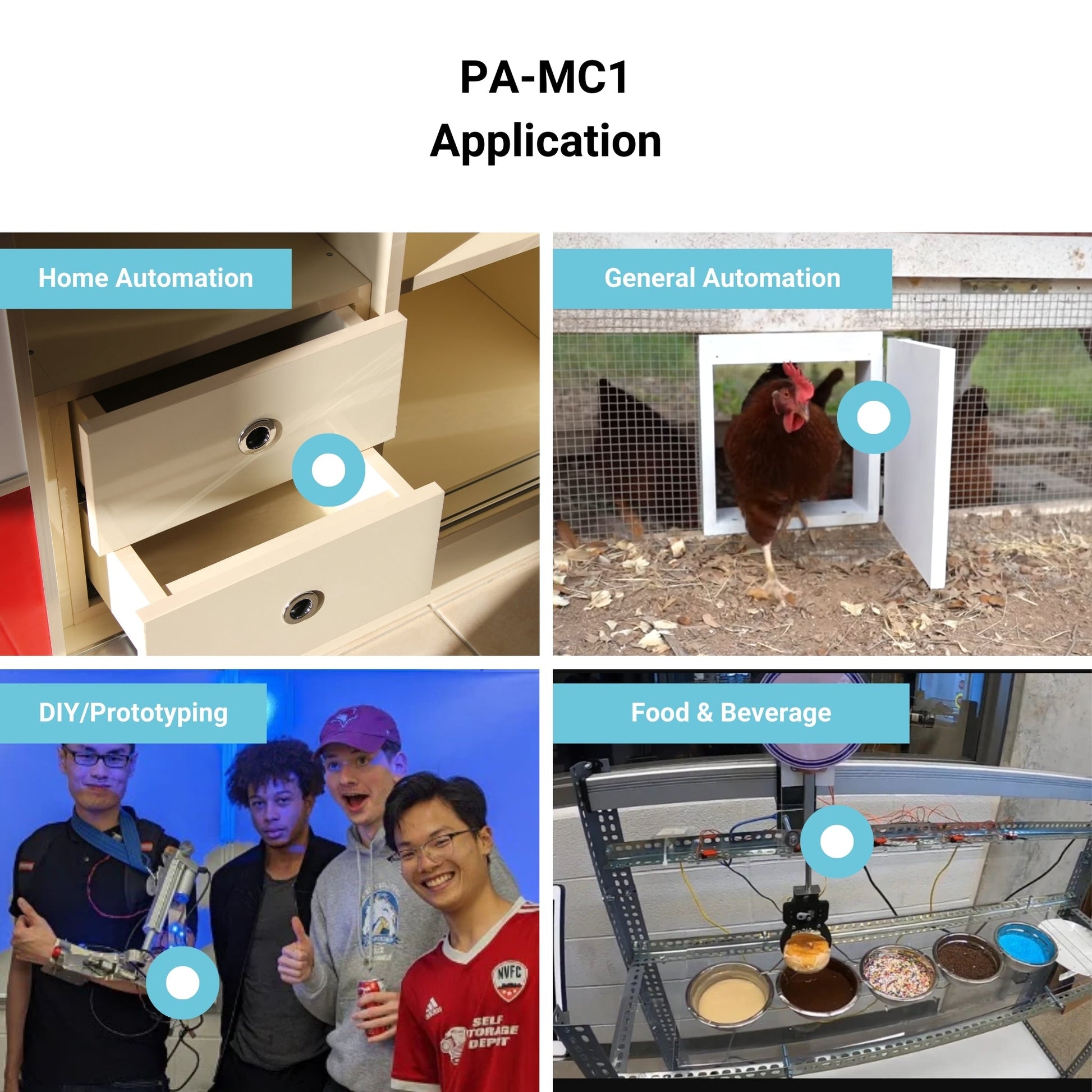

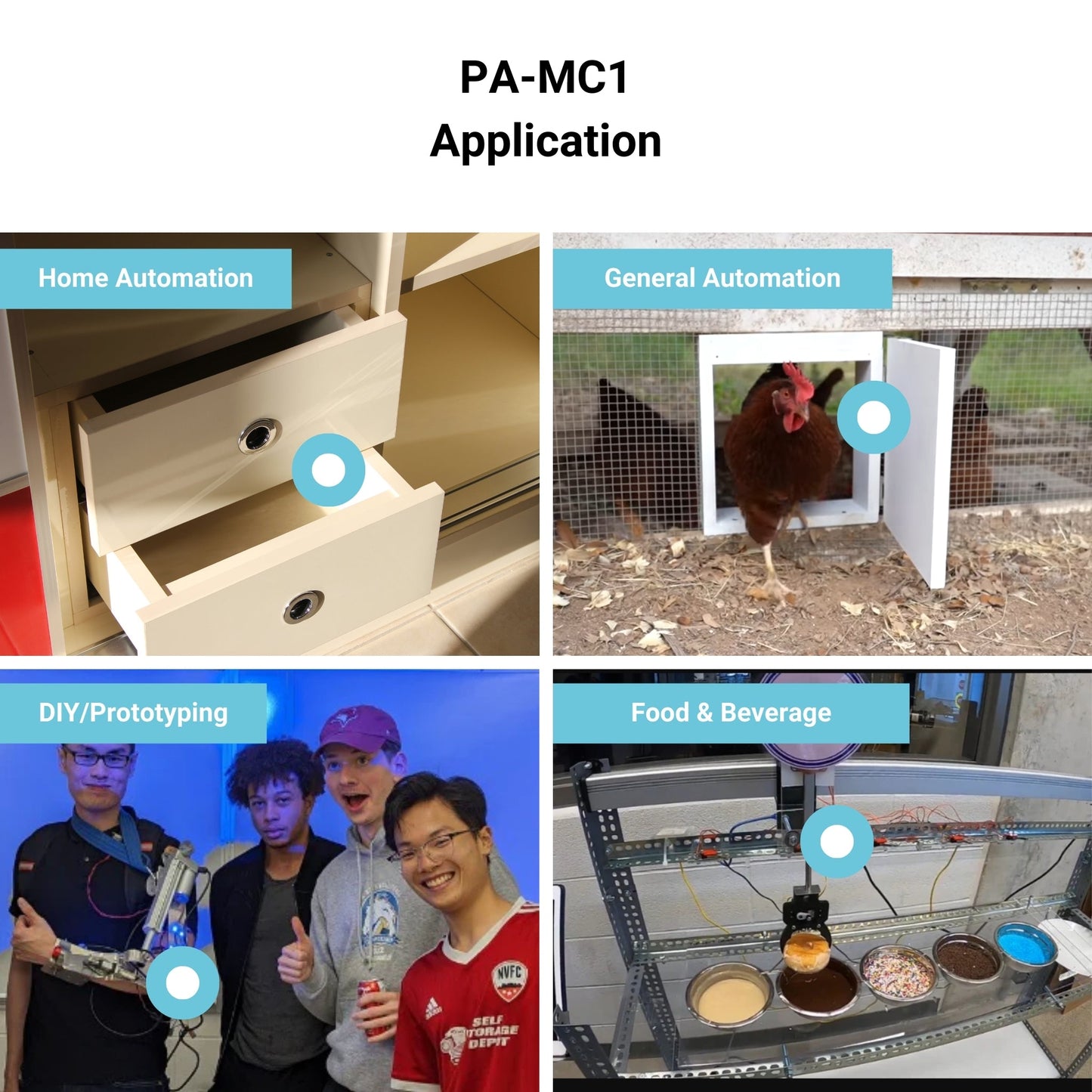

As our smallest linear actuators, the PA-MC1 micro linear actuators have a compact design that is ideal for use cases with limited spacing. We’ve specifically designed this unit to overcome common challenges found in many micro actuator solutions, such as:

- Versatile Force Ratings: Many micro actuators are limited to low force ratings that can lead to early mechanical failures. The PA-MC1 actuator addresses this with robust construction and quality motors to handle versatile force ratings in the given compact size.

- Safety Features: Standard models feature a current detection circuit that automatically halts the actuator at end-of-travel limits.

- Water Ingress and Seals: Advanced seals in the PA-MC1 actuator provide robust protection against water ingress, extending the actuator's life in outdoor environments.

Key Benefits and Features of the PA-MC1

- Versatile Force Ratings: Designed with reliability and versatility to handle 36-174 N dynamic and 36-249 N static force.

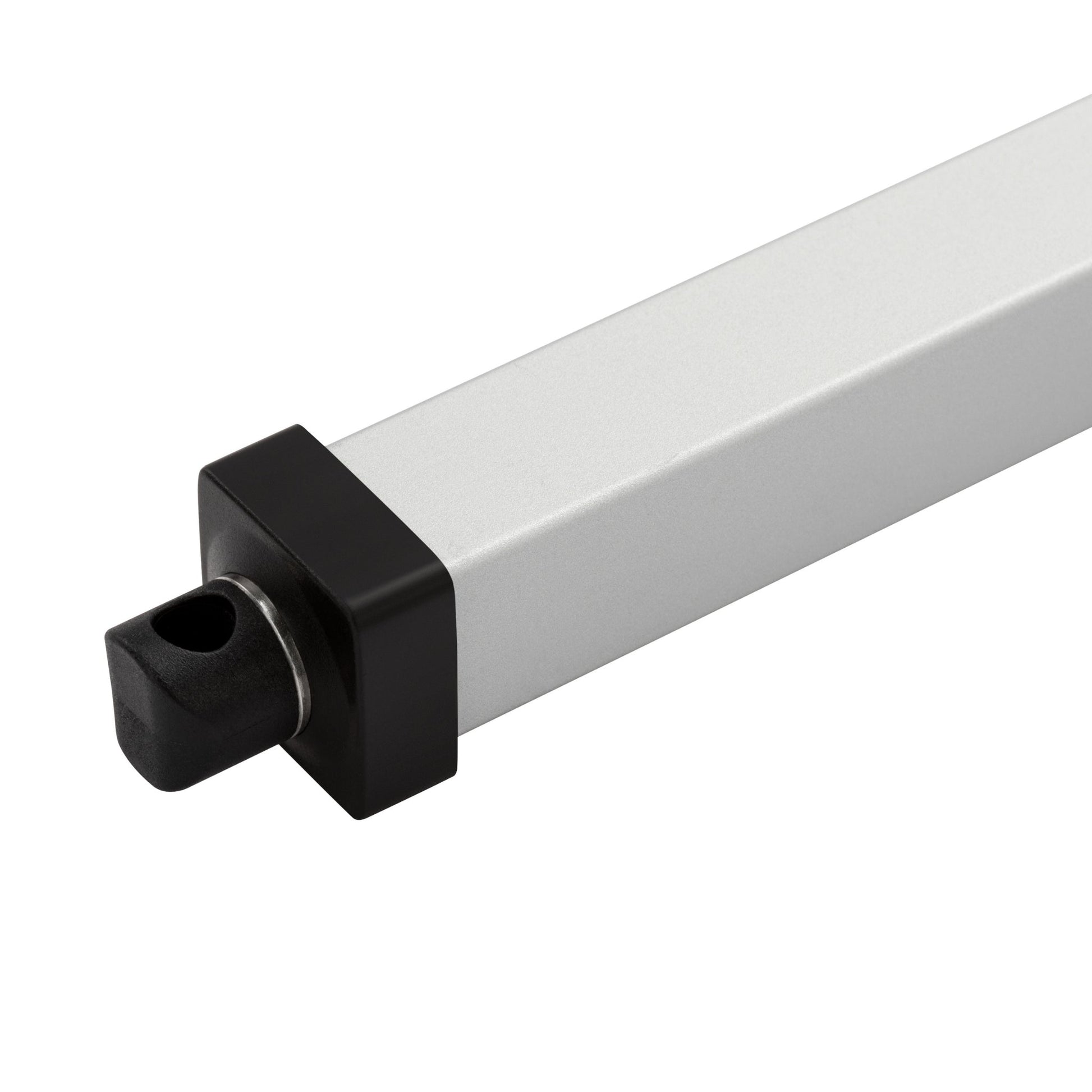

- Durable Construction: Built with long-lasting materials, including a stainless steel stroke rod and PA6-GF35 housing, ensuring reliable performance even in harsh conditions.

- Weather Protection: Rated IP65, offering excellent resistance against dust and water, making it suitable for outdoor environments.

- Operational Efficiency: Brushed DC motor with 20% duty cycle for efficient operation within specified timeframes.

- Integrated Overload Protection: Built-in, overload protection safety feature automatically halts the actuator at end-of-travel limits.

PA-MC1 Specifications

As our smallest linear actuators, the PA-MC1 micro linear actuators have a compact design that is ideal for use cases with limited spacing. We’ve specifically designed this unit to overcome common challenges found in many micro actuator solutions, such as:

- Versatile Force Ratings: Many micro actuators are limited to low force ratings that can lead to early mechanical failures. The PA-MC1 actuator addresses this with robust construction and quality motors to handle versatile force ratings in the given compact size.

- Safety Features: Standard models feature a current detection circuit that automatically halts the actuator at end-of-travel limits.

- Water Ingress and Seals: Advanced seals in the PA-MC1 actuator provide robust protection against water ingress, extending the actuator's life in outdoor environments.

Key Benefits and Features of the PA-MC1

- Versatile Force Ratings: Designed with reliability and versatility to handle 36-174 N dynamic and 36-249 N static force.

- Durable Construction: Built with long-lasting materials, including a stainless steel stroke rod and PA6-GF35 housing, ensuring reliable performance even in harsh conditions.

- Weather Protection: Rated IP65, offering excellent resistance against dust and water, making it suitable for outdoor environments.

- Operational Efficiency: Brushed DC motor with 20% duty cycle for efficient operation within specified timeframes.

- Integrated Overload Protection: Built-in, overload protection safety feature automatically halts the actuator at end-of-travel limits.

Following a set of standards is crucial for businesses to ensure their products and services can meet a level of quality that promotes customer satisfaction. At Progressive Automations, we aim for nothing but the best for our customers and strive toward continual improvements. Because of this, we are excited to announce that Progressive Automations is now ISO 9001:2015 certified!

Quality You Can Trust – Learn More2D/3D models

PA-MC1 3D Models

Videos

Related blog articles: