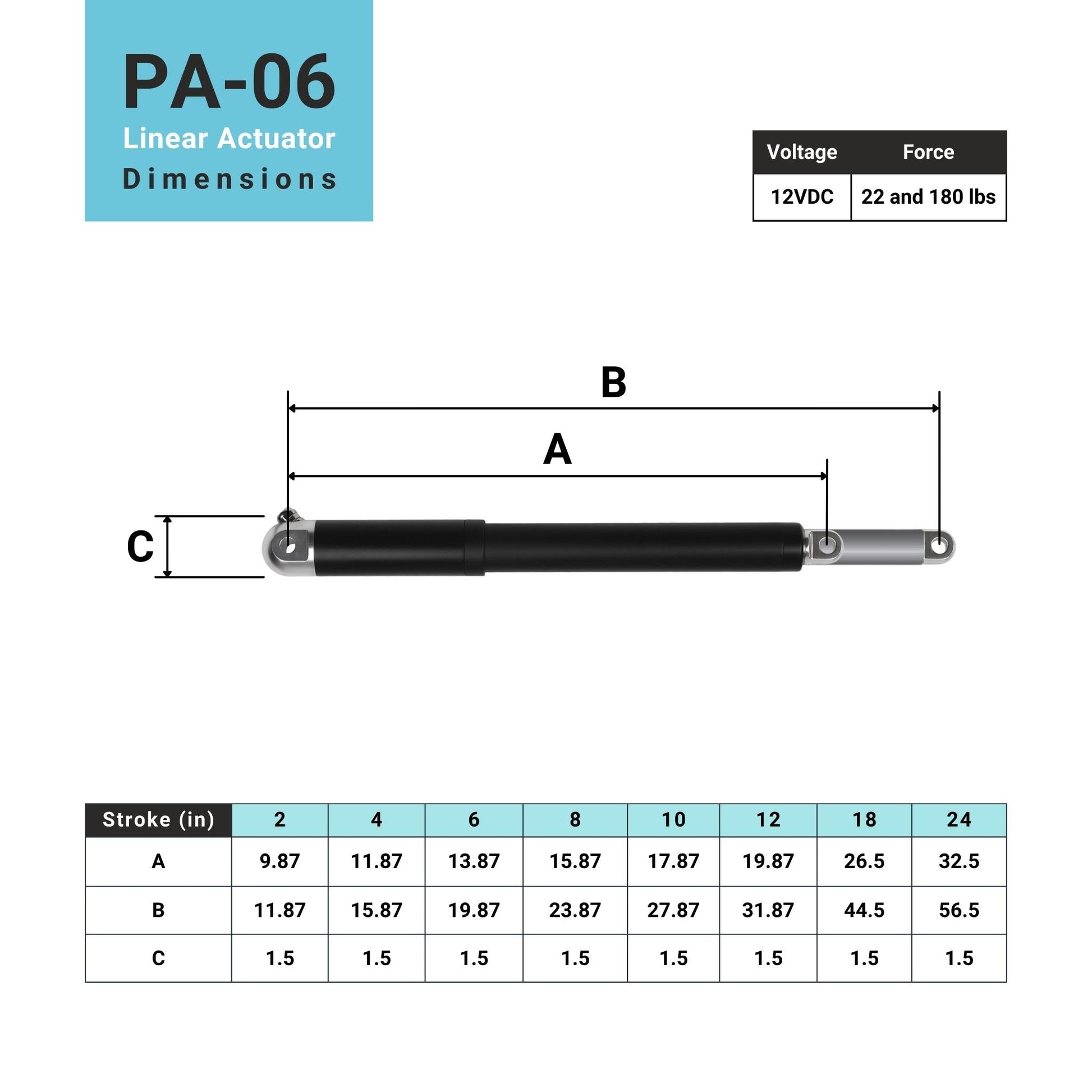

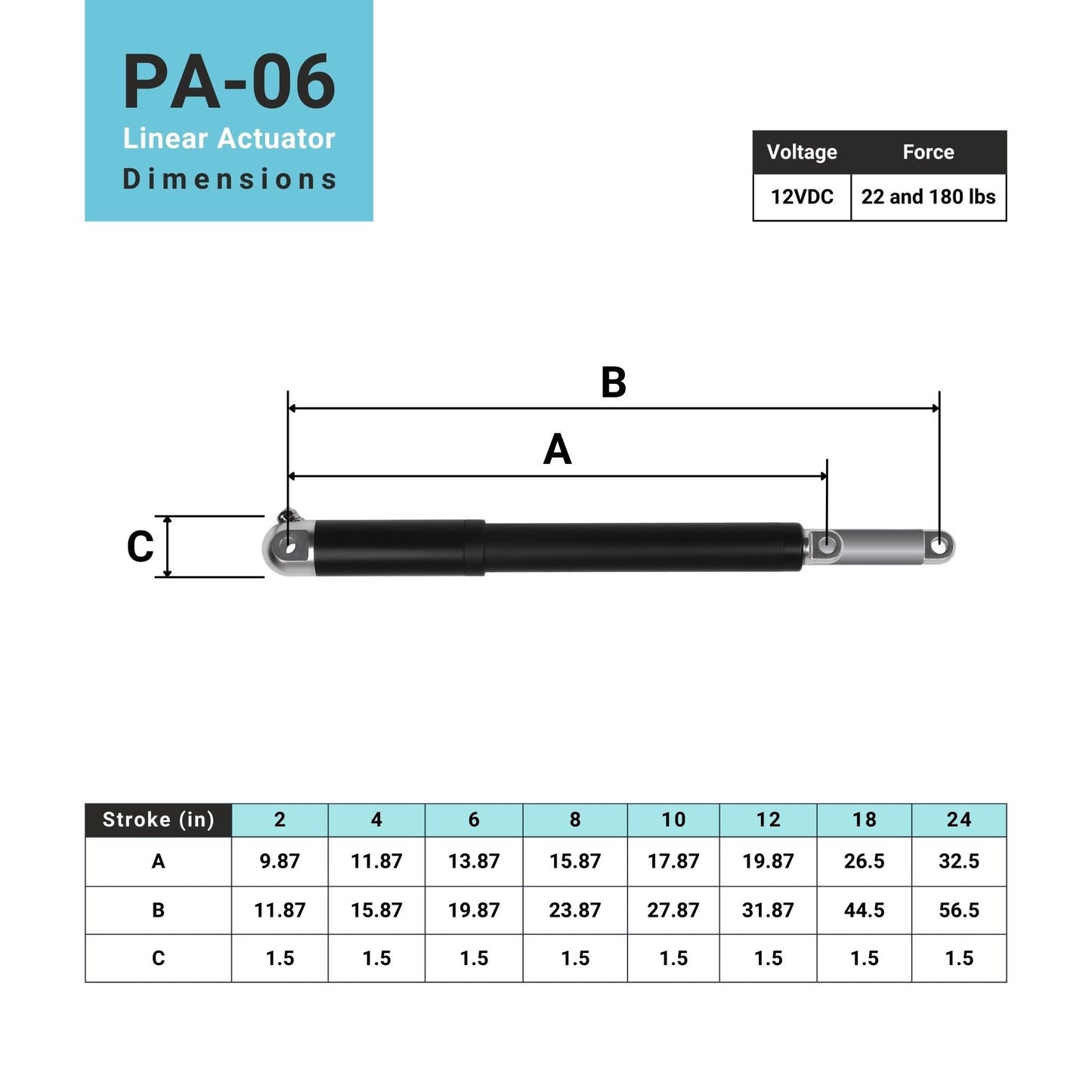

PA-06 Specifications

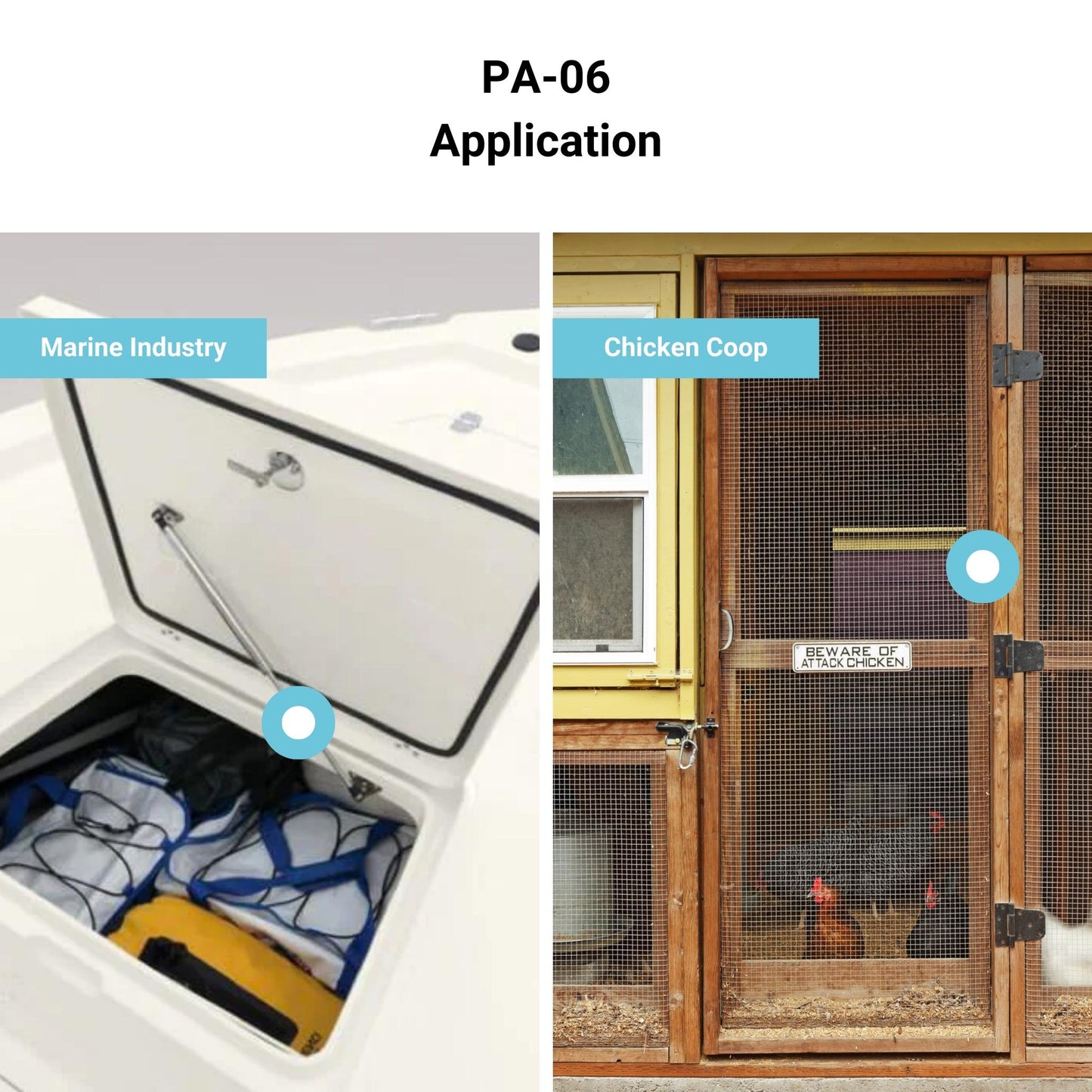

The PA-06 Waterproof Linear Actuator has one of the highest protection ratings out of all our linear actuators in a tubular form factor. We’ve specifically designed this unit to overcome common challenges found in many tubular actuator solutions, such as:

-

Mechanical Wear and Tear: Many tubular actuators are prone to early mechanical failures over time. The PA-06 actuator addresses this with robust construction and quality motors designed for longevity.

-

Safety Features: Built-in limit switches ensure the actuators automatically shut off electrical power when reaching the end of full retraction and extensions.

-

Water Ingress and Seals: Advanced seals in the PA-06 actuator provide robust waterproof protection against ingress, extending the actuator's life in a wide range of harsh environments.

Key Benefits and Features of the PA-06

-

Versatile Force Ratings: Designed with reliability and versatile capabilities to handle 98-800 N dynamic and 147-1600 N static in a sleek tubular design.

- Durable Construction: Built with long-lasting materials, including a stainless steel 304 stroke rod and aluminum 6063 housing, ensuring reliable performance even in harsh conditions.

- Weather Protection: Rated IP67M, offering excellent resistance against dust and water, making it suitable for a wide range of harsh environments.

-

Low Current Draw: The DC motors draw 2.5-3.7 A fully loaded to ensure high efficiency in any application and avoid excessive power drain.

- Integrated Limit Switches: Built-in, non-adjustable limit switches ensure precise control of the actuator's motion, enhancing safety and reliability.

PA-06 Specifications

The PA-06 Waterproof Linear Actuator has one of the highest protection ratings out of all our linear actuators in a tubular form factor. We’ve specifically designed this unit to overcome common challenges found in many tubular actuator solutions, such as:

-

Mechanical Wear and Tear: Many tubular actuators are prone to early mechanical failures over time. The PA-06 actuator addresses this with robust construction and quality motors designed for longevity.

-

Safety Features: Built-in limit switches ensure the actuators automatically shut off electrical power when reaching the end of full retraction and extensions.

-

Water Ingress and Seals: Advanced seals in the PA-06 actuator provide robust waterproof protection against ingress, extending the actuator's life in a wide range of harsh environments.

Key Benefits and Features of the PA-06

-

Versatile Force Ratings: Designed with reliability and versatile capabilities to handle 98-800 N dynamic and 147-1600 N static in a sleek tubular design.

- Durable Construction: Built with long-lasting materials, including a stainless steel 304 stroke rod and aluminum 6063 housing, ensuring reliable performance even in harsh conditions.

- Weather Protection: Rated IP67M, offering excellent resistance against dust and water, making it suitable for a wide range of harsh environments.

-

Low Current Draw: The DC motors draw 2.5-3.7 A fully loaded to ensure high efficiency in any application and avoid excessive power drain.

- Integrated Limit Switches: Built-in, non-adjustable limit switches ensure precise control of the actuator's motion, enhancing safety and reliability.

Following a set of standards is crucial for businesses to ensure their products and services can meet a level of quality that promotes customer satisfaction. At Progressive Automations, we aim for nothing but the best for our customers and strive toward continual improvements. Because of this, we are excited to announce that Progressive Automations is now ISO 9001:2015 certified!

Quality You Can Trust – Learn More2D/3D models

PA-06 Data Sheet

Videos

Related blog articles: